How Much Oil Is Used To Make Plastic

How practise we turn oil into plastic?

"Merely we humans brand waste that nature can't assimilate." Those are the words of oceanographer Capt. Charles Moore, who discovered the Great Pacific Garbage Patch in 1997. And, of course, he's talking almost plastic.

Nigh people reading this volition probably have something made of plastic within their line of sight. This material is ubiquitous: we're now producing more than 300 million tons (272 metric tons) of plastic a year, and roughly half of that is intended for single-use — pregnant that it'south discarded immediately later on information technology has served its purpose. This has led to a mounting problem of plastic waste material going to landfills, and some of this waste matter gets blown off course and makes its way into rivers and ultimately the sea. In fact, around 8 million tons (7.2 meg metric tons) of plastic pollution enters the ocean every year, where it entangles marine life, pollutes coral reefs and ultimately — subjected to degradation by water, wind and sun — breaks apart into trillions of tiny microplastic pieces.

These particles of plastic look a lot like food to many marine species, who then gorge on the pollution, and end up starving from lack of real diet. The surface of microplastics likewise attract pollutants in the ocean, and end up transporting these into the bodies of animals, with effects we're nevertheless trying to sympathise. There'south a possibility that microplastics could be harming humans as well, considering we consume them via seafood and even in drinking water: in 2019, the Earth Health Organization called for more research into the potential impacts of microplastic pollution on our wellness.

Related: How much plastic actually gets recycled?

Underpinning all this is the fact that, depending on the ingredients used to make it, plastic tin can be incredibly resilient and might never truly biodegrade (which for the purposes of this article, ways being efficiently reduced to bones reusable compounds in nature, by the microorganisms in h2o and soil). Pair that with the book of plastic pollution in our surround, and nosotros take a clear trouble. Near single-utilize plastics inbound the ocean, for instance, will stay there for centuries.

How did we create this crisis of persistent plastic? The answer lies in the procedure we utilize to make plastic itself. But starting time, it's important to understand that "plastic" isn't just the shopping numberless nosotros pic floating in the bounding main.

What is plastic?

"The term 'plastic' oft covers a broad range of heterogeneous materials, each with differing applications that require very different concrete properties," said Carl Redshaw, a chemist at the University of Hull in the United Kingdom and a participant in the academy's Plastics Collaboratory project, which conducts research to amend the sustainability of the plastics manufacture. "In fact, more 300 types of plastics are known," Redshaw told Alive Scientific discipline.

And then, if plastics are so different, what do they have in common? They're made of polymers, which are molecules comprising many repeating units, in formations that give plastics many of the desired qualities — such as flexibility, malleability and strength — that they often share. Beyond that, plastics more often than not autumn into one of 2 broad categories: bio-based plastics, in which polymers are derived from sources such as cornstarch, vegetable fats and bacteria; and so-called 'constructed' plastics, in which polymers are synthesized from crude oil and natural gas.

Despite the World-friendly name, bio-based polymers don't automatically have a expert environmental track record, because they may also persist in the environment and not biodegrade. "Not all bio-based plastics are biodegradable polymers, and not all biodegradable plastics are bio-based," Redshaw explained. Nevertheless, oil- and natural gas-derived materials comparably cause the starkest environmental harm, because plastics in this category tend to persist in the environment for longer — while causing other environmental impacts, besides.

To understand why, we're going to look at an case of oil-derived plastic: take the milk bottle chilling in your fridge. This carton begins its life somewhere far more than dramatic — deep in the bowels of the World, as crude oil. This substance, pooling in high-pressure level chambers within the World's crust, is drilled and pumped to the surface and carried through pipelines to oil refineries. Its dense sludge is made up of hydrocarbons, compounds fabricated from combinations of carbon and hydrogen atoms that form bondage of varying lengths, giving them different backdrop. These hydrocarbons are the earliest raw materials of plastic, ready-fabricated by the Earth.

Related: If y'all throw a compostable cup in the trash, does it still pause down?

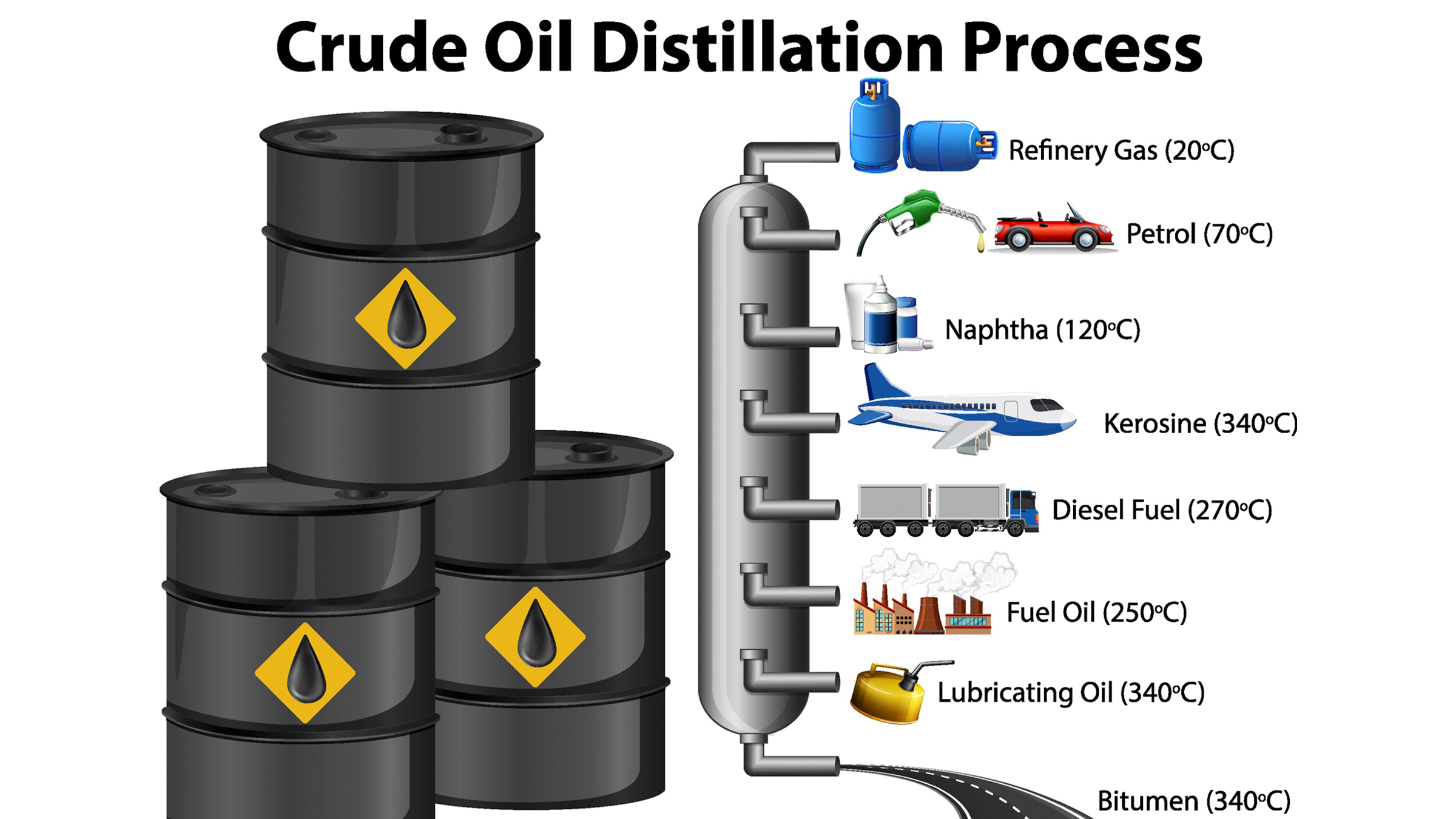

At the refinery, plastic production is truly set up in motility. Here, molasses-like crude oil is heated over a furnace that separates the hydrocarbons into dissimilar groups— based on the number of atoms they contain and their resulting molecular weight — so feeds them into a nearby distillation tube. Within this tube, the longer, typically heavier hydrocarbons sink to the lesser, while the shorter, lighter ones ascent to the tiptop. The result is that crude oil gets separated into several distinct groups of chemicals for apply — such as petroleum, gasoline and methane series — each of which contains hydrocarbons of a similar weight and length. One of these groups is naphtha, a chemical that will become the main feedstock for making plastic.

Naphtha is like aureate grit for plastic production, because two of the many hydrocarbons information technology contains are ethane and propene. These 2 compounds are crucial to the formation of the about unremarkably produced and ubiquitous plastic products on Earth, including the type used for that milk carton. Simply to be fabricated into something that tin can actually exist used to build plastic, ethane and propene have to be broken down from their raw hydrocarbon country into smaller units.

In that location are unlike means to do this. One method is to apply high heat and loftier pressure in a zero-oxygen environment. This procedure, chosen "steam slap-up," breaks down the hydrocarbons into shorter molecules called monomers.

"Monomers such as ethylene from ethane, or propylene from propene, can be derived direct from naphtha later thermal great," (which incorporates steam cracking), said Payal Baheti, a postdoctoral researcher at Aston University focusing on sustainable polymer materials. The simplified ethylene and propylene, finally, are the precious ingredients needed to brand plastic'southward backbone.

This side by side pace unfolds through a process chosen polymerization, wherein those private monomer ingredients are combined chemically in new arrangements to produce the long repeating chains known every bit polymers. In this case, ethylene and propylene course polyethylene and polypropylene — the 2 virtually common and widely produced polymers on Earth.

So, why are these two polymers so popular? Polyethylene's makeup allows it to be used to make plastics of different densities — pregnant it can be flimsy and pliable, or sturdy and tough — thus making its applications extremely various. Meanwhile, polypropylene's configuration makes it peculiarly flexible and resilient. Consequently, nosotros see these types of plastic every day, predominantly in single-use items such as the milk carton, not to mention plastic wrappers, straws, water bottles, shopping bags, shampoo containers, bottle caps — the listing goes on.

Related: What happens inside a landfill?

Yet, these are simply two varieties of constructed plastics out of many dozens more. Other types of hydrocarbons are isolated and cleaved down from dissimilar sources — not just from crude oil but too from natural gas — and are used to make plastic, too. In some cases, polymers might exist made of a single monomer, repeated, as we run into in polyethylene and polypropylene, or they might involve combinations of a few types of monomers.

What's more, each of those polymer chains will then exist processed in a diversity of ways and mixed with various additives — antioxidants, foaming agents, plasticizers, flame retardants — that equip them to fulfill the multifariousness of niche functions that brand plastics then versatile.

"Different plastics need to take different properties," Baheti told Live Science. "Take the example of food packaging, which should deter the passage of excess oxygen or sunlight, to avoid degradation, and so it contains additives to make it so. "I could say it'southward the additives that give a polymer its backdrop and leads to the formation of a plastic."

These last flourishes create the huge diverseness of plastic products we accept today — and that brand enormous contributions to food production and storage, cosmetics, applied science, medicine and health care.

"Conflicting material"

Now, permit'due south fast-frontwards through that production process one time more. Plastic that's synthesized from oil and natural gas is fabricated past isolating hydrocarbons, breaking them downwards into their component parts and and so reconstituting these parts into entirely new formations never earlier seen in nature. Just speaking, this creates an "alien" material unfamiliar to microbes in Earth'south water and soil, Baheti explained. "The carbon backbone found in synthesized plastic is non recognized past soil'due south bacteria, pregnant they cannot digest and convert it into water and carbon dioxide."

"The likes of polyethylene can take centuries to decompose in landfill sites," Redshaw said. "This means much of what has been produced during our lifetime however remains in its virtually original form. And persistence isn't the but issue: as it gradually breaks apart nether the influence of sunshine, water and wind, oil- and natural gas-derived plastic releases greenhouse gas emissions contained within, also as leaching the chemicals added during production back into the environment. The sheer volume of single-use plastic pollution, especially — combined with its persistence and an ongoing environmental impact that can last for centuries — has created the environmental catastrophe we see today.

Related: How much trash is on Mountain Everest?

But at that place may be a fashion out of this mounting pile of trash. Redshaw believes biodegradable plastics — which are a focus of his research — could be one potential solution. To rehash, making biodegradable plastic doesn't necessarily mean producing it from bio-based sources like corn starch (although that could provide a solution). More than specifically, it entails making plastic from polymers that can be broken downward reasonably efficiently by microbes in water and soil.

For this to have existent planetary bear on, biodegradable polymers would need to replace the likes of oil-based polyethylene and polypropylene — but while also maintaining backdrop similar strength and flexibility that make these conventional polymers so desirable. That's a alpine social club, fabricated trickier by the fact that conventional polymers remain competitively cheaper to make.

But a few biodegradable options are starting to make headway. One is a blazon called polylactides, which are being used to make single-use items such every bit cups, cutlery and straws, that could biodegrade more effectively once they're in the environs. These kinds of inventions are likely to increment as global pressure grows to make plastic more sustainable, Redshaw reckoned.

In that location are hints of optimism elsewhere, too. In 2016, researchers discovered plastic-eating bacteria, and others have since identified polyethylene-munching worms (this beastie is a caterpillar of the greater wax moth, Live Science previously reported). They've also found enzymes that can exist engineered to intermission down plastic waste product.

"Maybe, in the years ahead, we will learn from the bacteria and worms that possess the ability to pause down and assimilate plastics, fifty-fifty stuff like polyethylene carrier numberless, and design big, artificial worms that can eat their way through our plastic waste material — like the giant maggots that featured in 'Medico Who' back in the '70s!" Redshaw said.

In whatever case, in the process of creating plastic, humans have managed to take raw materials from nature and transform them so thoroughly that nature no longer recognizes them. Our ingenuity is what got us in this mess; now, hopefully, it can get united states of america out.

Originally published on Alive Scientific discipline.

How Much Oil Is Used To Make Plastic,

Source: https://www.livescience.com/how-oil-is-turned-into-plastic.html

Posted by: baltzcoonly63.blogspot.com

0 Response to "How Much Oil Is Used To Make Plastic"

Post a Comment